As in the past, there have been and are many factors affecting the change and transformation of societies. For example, the industrial revolution, climate change, ecological problems, pandemics, and sustainability. Among these, the potential benefits of the fourth industrial revolution in industry and production compelled the transformation of brands, businesses, and societies.

However, while the fourth industrial revolution focuses on efficiency in industry and production, it needs to catch up on issues such as climate change, diseases, or ecological balance. This system, referred to as Society 5.0 or Industry 5.0 in the literature, has been designed to fill these areas’ gaps. Society 5.0 refers to the transition from information societies that emerged with Industry 4.0 to super-intelligent communities, a more sustainable model.

Super Smart Textile Industry

One of the main challenges facing the textile and fashion industries is the consumption of natural resources and their impact on the environment, including hazardous chemicals and textile waste. At Copenhagen Fashion Week this year, to reduce its impact on the environment, participating brands were required to comply with the requirements of a certain number of sustainability directives.

What steps can the textile industry take in these changes, which we have personally witnessed in the fashion industry? The technological change in the world and the resulting integration of concepts such as artificial intelligence, the internet of things (IoT), robotics, blockchain, nanotechnology, and digital transformation into daily life is an event that we all know. In the textile sector, these developments are progressing rapidly.

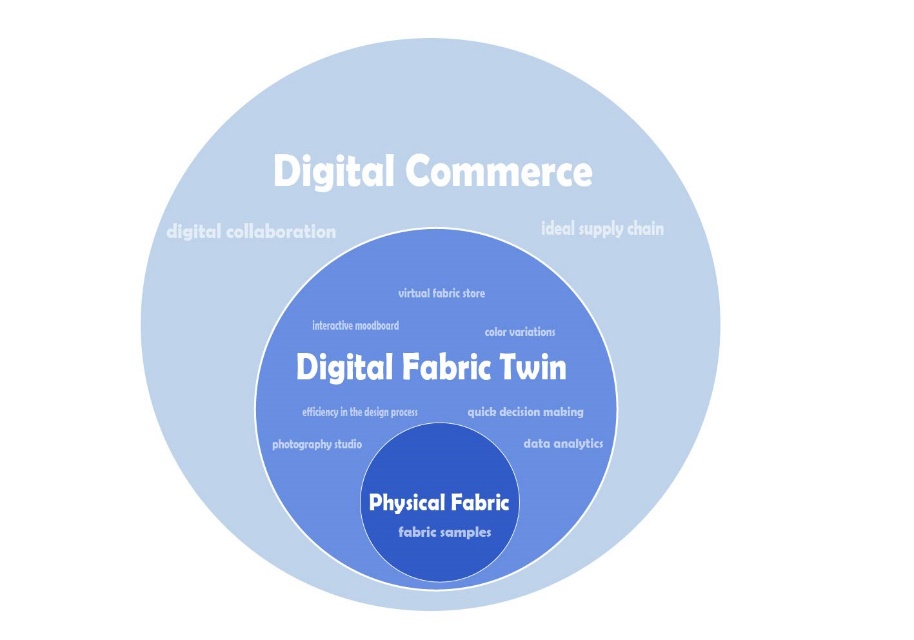

Well, after all this, what would you imagine if I told you about the internet of fabrics? Style3D is a company that develops technology that offers a one-stop solution for fabric digitalization, just as I mentioned. In addition, it has a technology that makes collaborations between fashion brands and suppliers more digital. What kind of technology does Style3D fabric digitization with all these features combine with what information?

Smart Scanner: Digitizing Fabric Devices

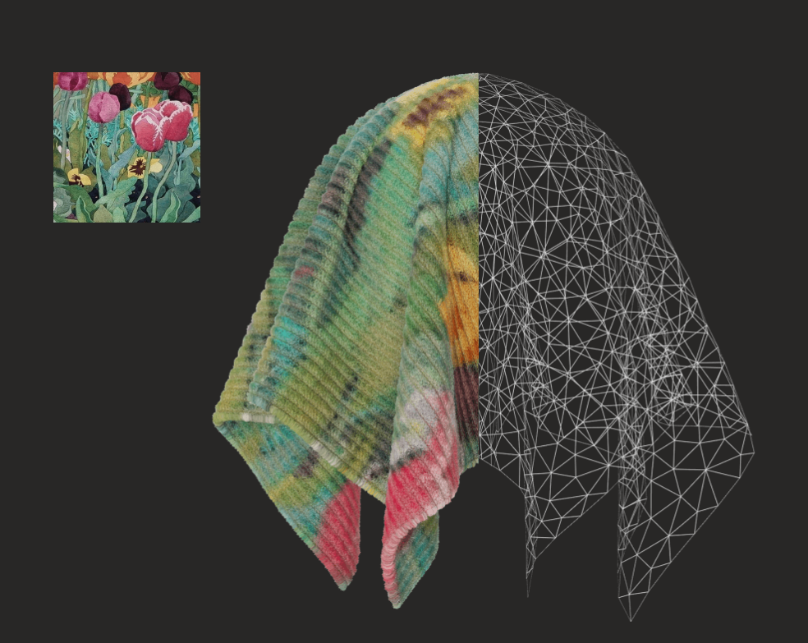

With the Style3D Fabric structure scanner, many properties of the fabric, such as usual transparency, metallicity, and roughness, can be transferred to digital.

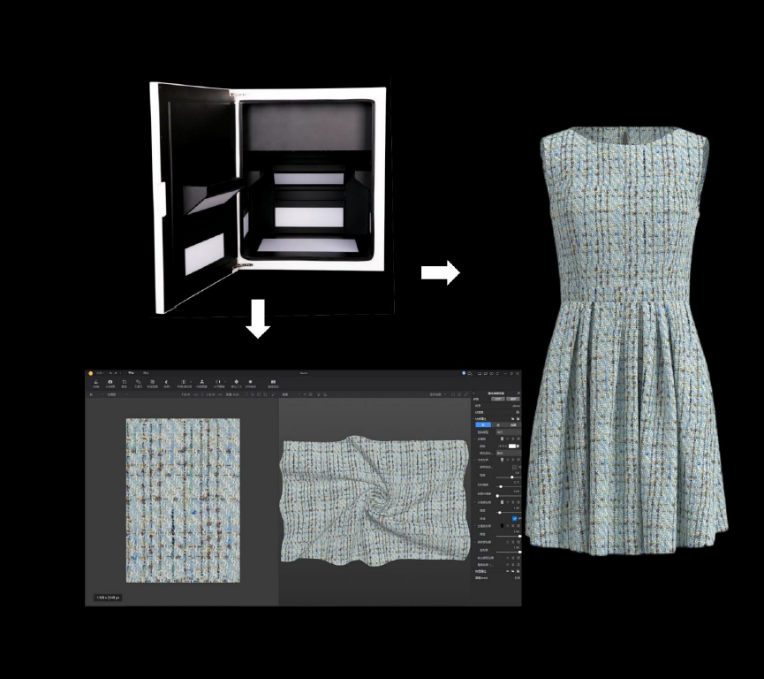

Style3D fabric measures the physical parameters of the fabric, such as weight, thickness, tensile strength, and bending strength, with the 3D fabric tester and can transfer the digital of the fabric to the physical twin.

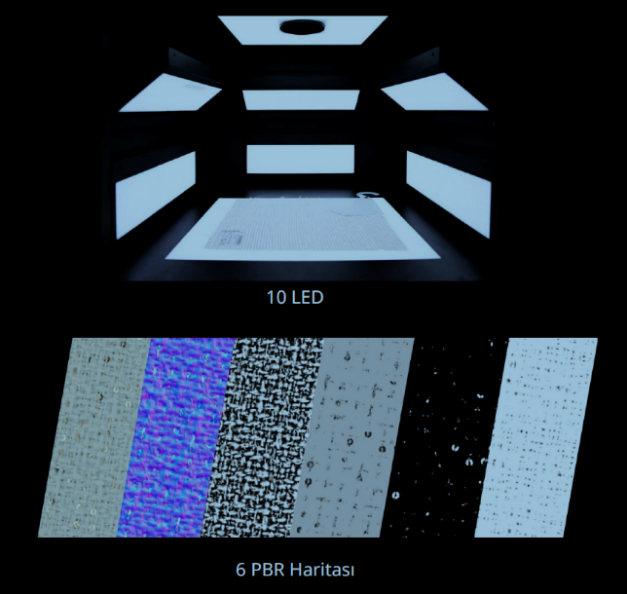

Style3D Fabric’s 3D fabric scanner is designed as a master of detail. With the high light sensitivity of the device, more realistic colors can be obtained. It captures up to 45.7 million pixels in every aspect of the piece. It automatically generates 6 PBR maps that transform fabric into digital art and harmonize with almost any fabric texture. In addition, 10 LED 6 PBR maps are available, higher than other 3D scanners.

Fabric digitization tools and direct and easy connection to Style3D Fabric software are available. Style3D Fabric’s fabric tester ensures accurate measurement and efficient operation. Instead of manual tests, only get results provided. Style3D Fabric Software is directly linked to multidimensional data for high accuracy.

What benefits can you achieve using Style3D fabric digitization

- Contribution to green fashion due to a reduction in water and electricity,

- Reduction in the workforce,

- Increasing the efficiency of the design process with the digital twin,

- Instant viewing of color variants,

- Quick decision making,

- Interactive mood boards,

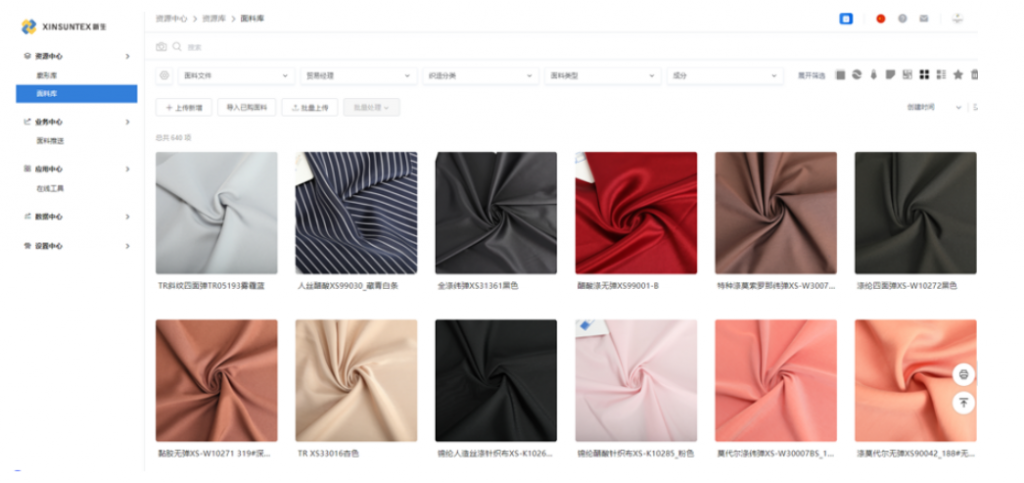

- Virtual fabric store,

- Data analytics,

- Savings on photo shoots,

- QR code and digital label,

- Optimizing the process,

- Reducing the cost,

- The ideal digital supply chain.

Inspiration Board: Interactive

Before starting a design, a designer must work with key images that will inspire him and align with the trends. While presenting this, he can speed up the process using Style3D’s interactive inspiration boards and realize the presentation that will contribute to the sale in virtual showrooms where the buyer can understand the design concept.

Design Process: Digital Twin!

In the manual design process, the fabric selection process takes place when a brand designer inspects the fabric at a booth at a fabric fair or trade show. While the swatch of the physical fabric is essential for the design process, the design process is interrupted because the designer is subject to the ongoing manual process when he returns to the workplace the next day. Rather than waiting for color samples to be sent from the fabric manufacturer, the design process can become instantly efficient with Style3D’s digitized physical fabric twin.

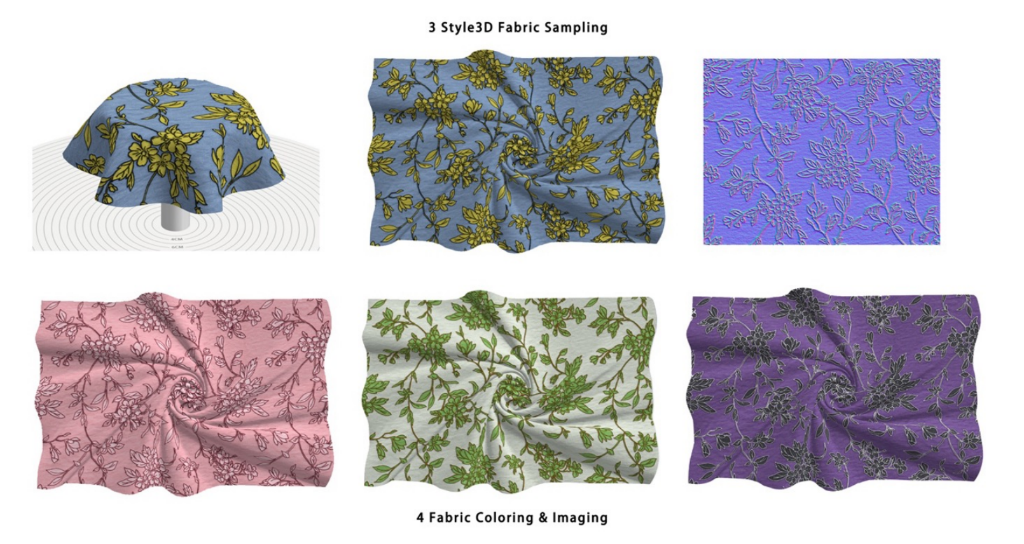

Sample Confirmation Process: Color Variations

Digital fabric swatches enable faster decision-making and more efficient collaboration with customers. In addition, designers can download the fabric’s digital twin and start working sooner, which means significant time savings.

With the fabric’s digital twin, the manufacturer can quickly test many design concepts while reducing the number of physical samples and creating new color groups. In addition, Style3D can instantly present digital fabric collections to customers using three-dimensional product simulations.

Lifelike previews make it easier for the customer to approve the product, thus increasing the sales and marketing capabilities of the manufacturer.

Green Fashion:Protect Our Earth

Digital fabric production has much less energy, waste, and carbon footprint. No water or chemicals are used to create or use digital fabric. As a result, producing a digital fabric leaves less carbon footprint than a physical textile.

The primary purpose of the production of digital fabric is quality, not production speed. Yet the rate is much faster than physical fabric production. This means that the fast demand can only be met with digital textiles without using raw materials. Once the physical fabric is processed in 3D with Style3D’s fabric scanning devices, it can be used indefinitely.

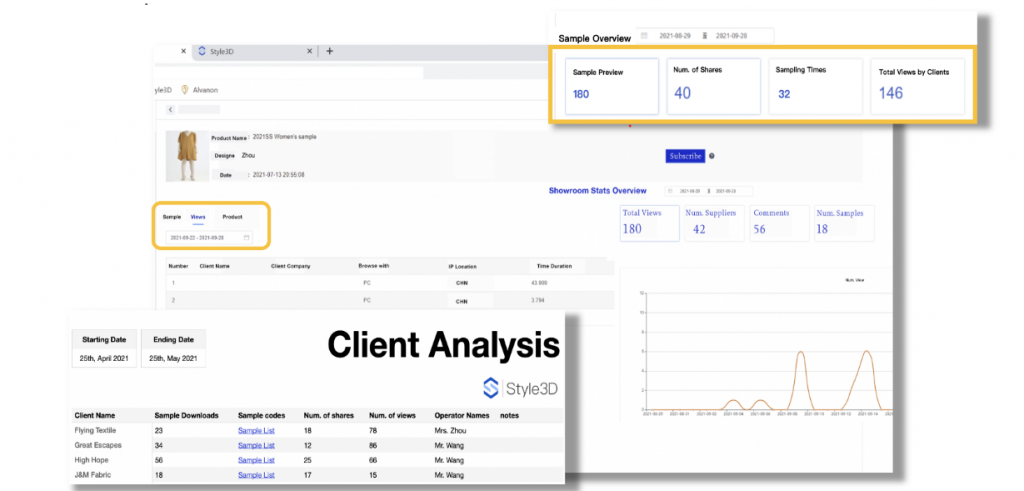

Data Analysis: Rational Approach

With the data provided by Style3D, you can manage your business and make decisions based on facts and numbers rather than assumptions or gut feelings. As a pioneer in 3D material data collection, Style3D has become a part of many design and material creation processes of brands and fabric factories thanks to material digitization technologies.

Photo Shooting Process: Time+Cost Saving

Because of the efficient scalability of 3D views compared to physical shots, you can save time and cost in product photography for online stores with digital fabrics.

Style3D Fabric digitizing devices and software offer the textile industry tremendous opportunities to be more sustainable while increasing creativity and performance. Adopting digital structure in design, decision-making, and sales processes provides significant savings and a much higher efficiency. With Style3D Fabric, you can prepare your place for your brand or business in the digital age, where information and technology are combined.

Source:

https://landingpage.style3d.com/style3d-digital-fabric-solution (02. 22.2023).

https://dergipark.org.tr/en/download/article-file/2020475 (02.22.2023).

https://copenhagenfashionweek.com/sustainability/designer-requirements- sustainability-action-plan-2020-2022 (02.22.2023).

https://myfashionupdates.com/2023/02/03/copenhagen-fashion-week-and-sustainability/ (03.02.2023).