In such a global industry, European textile companies cannot compete on price alone. They need to differentiate their offerings by focusing on design, quality, and innovation, while also optimizing processes and reducing costs.

One of the main challenges the textile and clothing industries face is their impact on the environment, including natural resources consumption, hazardous chemicals, and textile waste.

Additionally, the pandemic has shaken industry foundations and disrupted global supply chains, while consumer behaviors are changing.

The Benefits of Fabric Digitalization

Digitization offers tremendous opportunities for the textile industry to increase creativity and performance while being more sustainable. Adopting digital fabric in the design, decision-making, and sales processes results in significant savings and a much higher productivity rate. The benefits of 3D for fabric manufacturers, garment makers, and brands are very similar. It helps to speed up the design process, facilitate samples storage, and reduce costs, resulting in better service and increased responsiveness.

Regardless, to truly improve design and sales processes, a virtual sample must precisely reproduce the physical behavior and visual aspects of its physical twin.

Efficiency In the Design Process

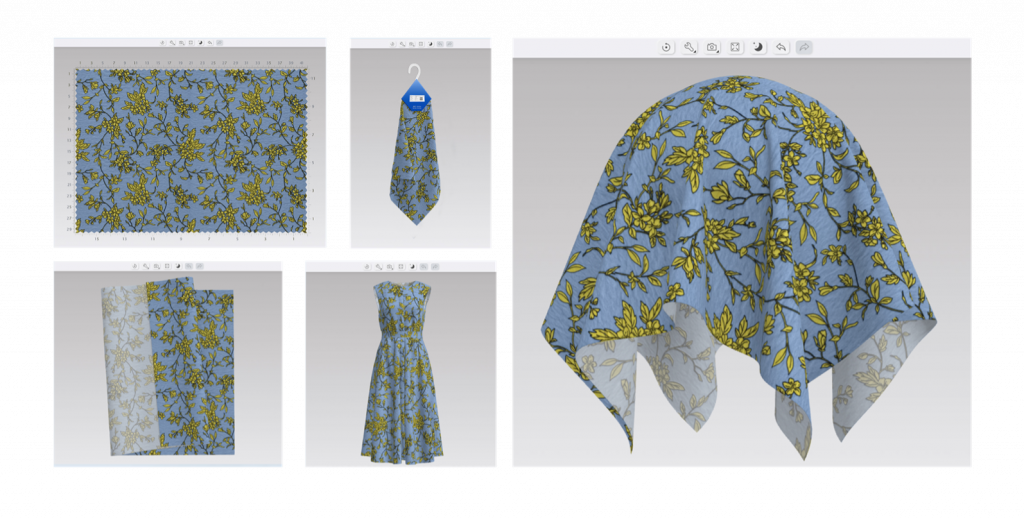

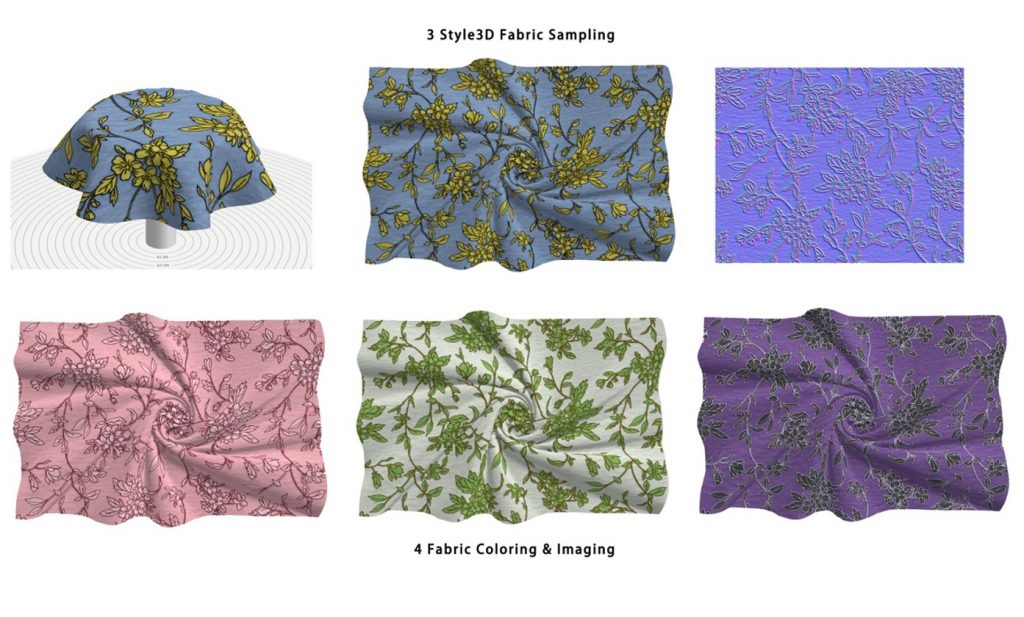

With a digital fabric twin, the manufacturer can easily test many design concepts and present seamless prints at varying scales. They can also show proposed garments from different angles and create new color variants.

At the same time, the number of physical colorway samples can be reduced, while also offering many variations in digital form.

A More Efficient Sales Process

Digital fabric swatches allow for faster decision-making and more efficient collaboration with clients.

The first selection process happens when a stylist examines fabrics at a trade show and requests a selection of samples. Back at HQ, they will have to wait several days to receive samples. If a fabric is presented alongside its digital twin, the designer can immediately download the digital fabric and begin working with it. A significant amount of time is saved.

Digital sampling enhances fabric selection, and collaboration, with designers and buyers.

Enhanced Precision, True to Life Representation

When selecting a material, it isn’t easy for a buyer or designer to envision a fabric or print on the final product. This is where 3D modeling really stands out. A textile manufacturer can instantly present its collections using 3D product visualizations generated with digital fabrics. These previews enhance the sales process and enable the buyer to visualize a finished product, before even selecting the material.

Interactive Inspirational Mood Boards

Mood boards allow designers to gather ideas, colors, and atmospheres in one place to define a coherent design concept. An interactive mood board goes one step further, connecting visual concepts – such as fabric, accessories, and models – to the final product. Interactive mood boards provide a prime source of inspiration for buyers and an excellent sales presentation tool that doesn’t require domestic or overseas travel.

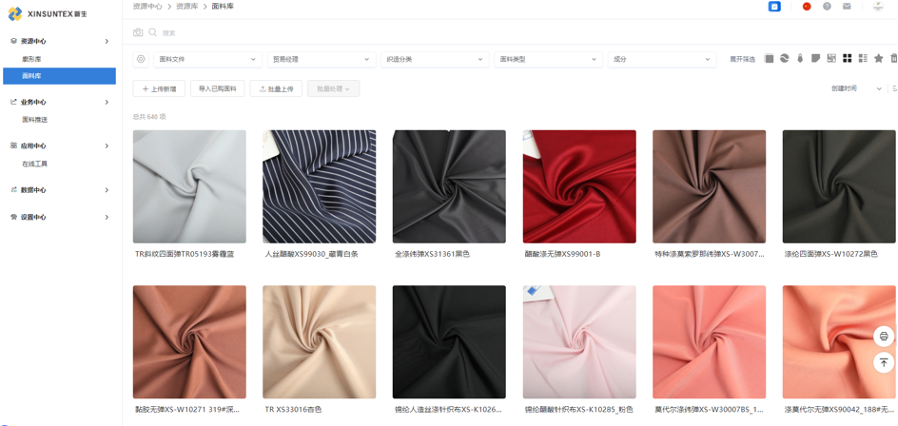

Virtual Fabric Showroom

The traditional showroom has been rocked by the plethora of changes that have disrupted the industry in recent times. The virtual textile showroom is an expression of new ways of working. In just one click, a buyer can access complete textile assortments and see their physical behaviors, visual characteristics and colorways. They can even try the materials out on finished products.

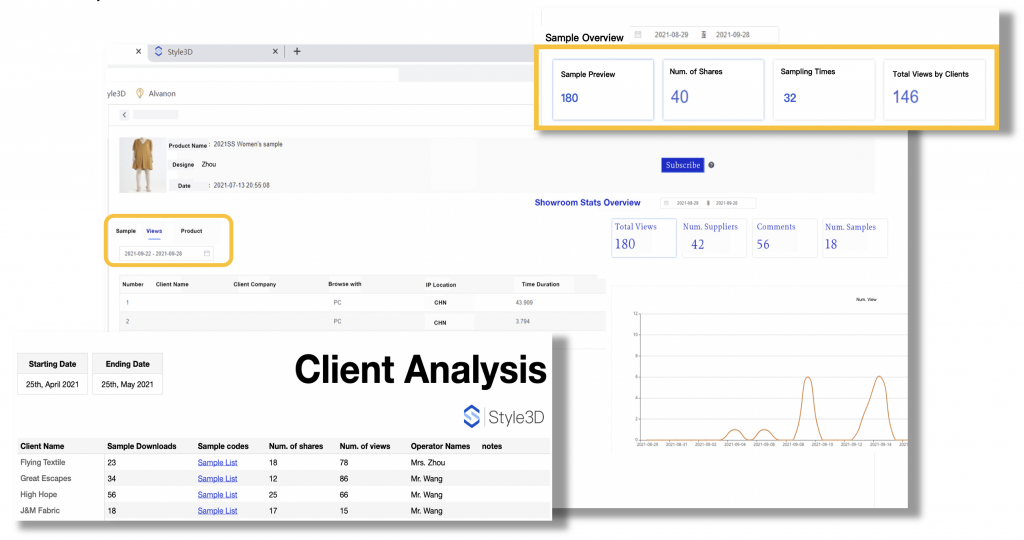

Access to Fabric Data and Analytics

Data and analytics can be used to drive a business and make decisions based on facts and figures, rather than gut feel. The Style3D platform allows manufacturers to see which fabrics, in which colors, are garnering attention. They can see who downloaded them, which ones aren’t proving popular, and so on. This valuable information can then be relayed to product developers.

Saving On Textile Photoshoots

A fabric supplier needs product photos for their online store. With digital fabrics, the time and cost savings are immense because of the efficient scalability of 3D renderings, compared to physical fabric shoots.

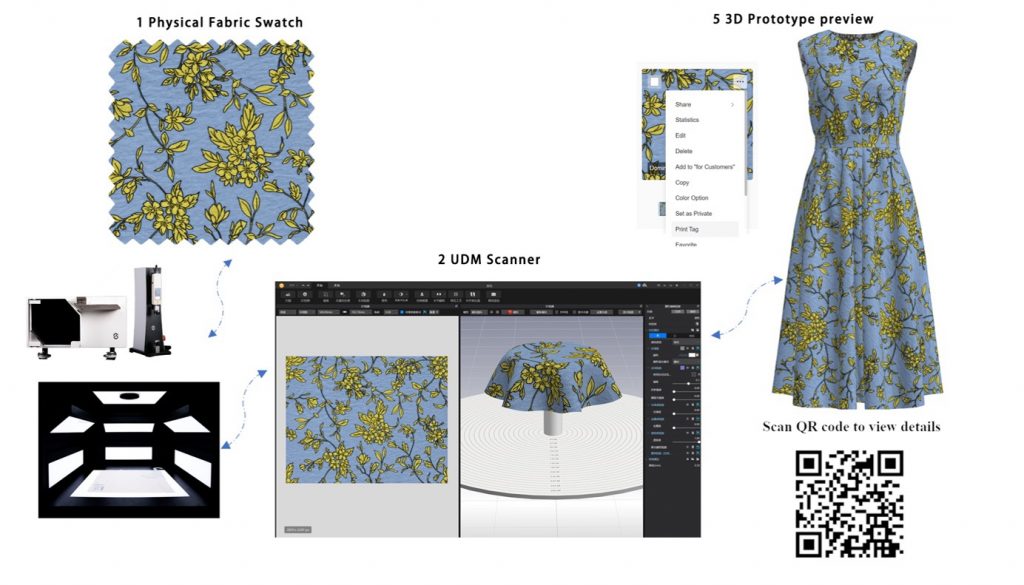

How Do Digital Fabric Assets Work?

What’s Behind the QR Code?

Not only can digital fabrics be beautifully displayed, they also come with QR code labels. Each code comes with a complete metadata set, physical properties, 3D visualizations, intelligent labeling systems, images, and videos.

A SALES TOOL

VIRTUALIZE

- True-to-life material applications

- Fabric look and feel on a final product

- All textile colorways

COLLABORATE

- Share QR codes with colleagues

MANAGE

- Fabric specs

- Access to online fabric showrooms

The best way to showcase a textile is by applying it to a physical garment prototype. It might not be possible to produce a sample for every fabric, but with Style 3D, it is easy to create a true-to-life digital sample for all swatches.

Case Stydy: MIZUDA

Based in Huzhou, Zhejiang, China, Mizuda is a leading producer of P/D and printed wovens, made in stretch and non-stretch cotton, and cotton blends.

Why Did Mizuda Adopt Style3D Technology?

Founded in 1993, Mizuda primarily engages in designing, developing, and manufacturing printing and dyeing products for cotton, linen, and woven materials. Through the continuous transformation of its business model, product innovation, and business development, the company has become a leading player in printing and dyeing products.

With the Internet’s advances, digitization of the clothing industry is an inevitable evolution. Being upstream in the clothing industry chain, fabric manufacturers are facing an urgent request for digital transformation, including the need for 3D fabrics.

Mizuda adopted Style3D to begin its digital transformation. This is a process to improve fabric sourcing and purchasing, enrich business presentations and digital marketing, and pursue a sustainable development model.

How does Mizuda collaborate with Style3D?

- Innovative presentation of their fabric collection vis-à-vis 3D Sampling and 3D VR Showroom

- Trend forecasting

- Internal and supply chain collaboration

- Analysis of fabric portal traffic

Using Style3D, Mizuda applies its fabrics to various 3D models so it can visualize colorways and drape. This interactive visualization allows for online adjustments and final validation with internal teams and buyers. In addition, colorways can be viewed and adjusted online using various avatars, which significantly improves the accuracy and cost-effectiveness of a development cycle. More importantly, 3D visualization helps promote fabrics to buyers, and thereby improve new customer acquisition and online sales.

Mizuda reports a 30% reduction in fabric samples and a 45% reduction in printing cylinders. This reduces direct sampling costs and resources consumption – such as water and electricity – thus mitigating environmental impacts. Last but not least, Mizuda reports that their labor productivity rate has increased by 180%!

Case Study: WENSLI

Founded in 1975, Wensli has its roots in Chinese silk, combining traditional silk with cultural innovation and cutting-edge technology. It also develops silk cultural products, high-end silk ornaments, and silk artworks based on traditional fabrics and garments

With its industry-leading, double-sided silk printing process, WENSLI has established strategic cooperation with many world-famous luxury brands in silk printing and fabric design.

Wensli West Lake One NFT, the combination of technology and heritage.

“Elegant appliqué, stunning colors, embellished with the elements of the Chinese zodiac tiger.” These brief descriptions are sufficient for designing a unique and personalized scarf, leveraging a precise AI algorithm.

With the West Lake One NFT digital creation platform, Wensli offers a new customization approach to its clients. The platform is an expression of their commitment to “allowing all individuals to become the designer.”

As a pioneer in breaking through the once-closed circuit between the virtual and physical realms, Wensli, as a trailblazer in the silk industry, undoubtedly pivoted from a legacy business to one at the vanguard of technological development and excellence.

On West Lake One NFT, the boundary between content creators and end customers becomes even more blurred. Users can switch between different avatars at will, and the release of the digital certificate, or NFT (non-fungible token), for the artpiece endows it with investment properties.

References:

- Textiles and the Environment The role of design in Europe’s circular economy – Eionet Report – ETC/CE 2022/2 – February 2022

- EU Textile and Apparel Industry and Trade Patterns (Updated January 2022) – FASH455 Global Apparel & Textile Trade and Sourcing

- European textile industry needs to grow its role on global markets – EURATEX – February 2022

- Hangzhou Jimay Printing & Dyeing Co. Ltd.

- Zhejiang Mizuda Textile Printing and Dyeing Technology Co., Ltd.

- Hangzhou Wensli Silk Sciences & Techniques Co Ltd.